VPSA PSA vacuum analytical oxygen plant

VPSA PSA vacuum analytical oxygen generation equipment

VPSA type PSA vacuum analytical oxygen production equipment takes PSA and vacuum analysis as the principle, uses high-quality calcium / lithium molecular sieve as the adsorbent, and directly obtains oxygen from the atmosphere.

Technical Indicators

Product scale: 100-10000n ㎥ / h

Oxygen purity: ≥ 70-94%

Oxygen pressure: ≤ 20KPa (superchargable)

Annual operating rate: ≥ 95%

Working principle

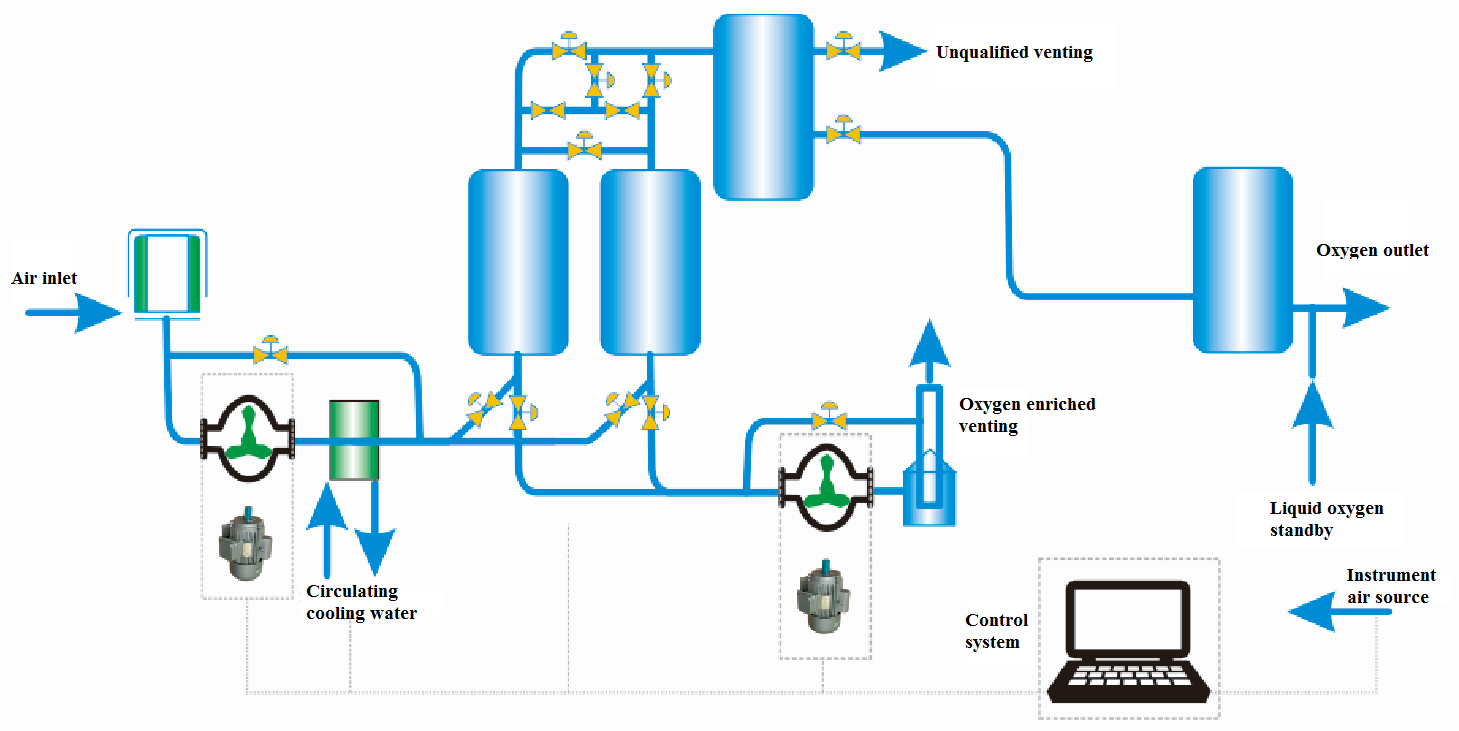

VPSA vacuum desorption oxygen production equipment is mainly composed of blower, vacuum pump, switch valve, adsorber and oxygen balance tank. The raw air is pressurized by roots blower into the adsorber filled with oxygen molecular sieve, in which water, carbon dioxide and nitrogen are adsorbed to produce oxygen. When the adsorption reaches a certain degree, vacuum pump is used to vacuum the adsorbed water, carbon dioxide, nitrogen and a small amount of other gas groups are respectively pumped out and discharged to the atmosphere, and the adsorbent is regenerated. The above process steps are controlled automatically by PLC and switching valve system.

Simplified flow chart

Air filter

Blower

Temperature regulation system

Adsorption system

Oxygen balance tank

Vacuum pump

Outlet silencer

Oxygen storage tank

Application Area

Metallurgical Industry: EAF steelmaking, blast furnace ironmaking, oxygen enriched shaft furnace combustion supporting

Non ferrous smelting industry: lead smelting, copper smelting, zinc smelting, aluminum smelting, various furnace oxygen enrichment

Environmental protection industry: drinking water treatment, waste water treatment, pulp bleaching, sewage biochemical treatment

Chemical industry: various oxidation reactions, ozone production, coal gasification

Medical industry: oxygen bar, oxygen therapy, physical health care

Aquaculture: Marine and freshwater aquaculture

Other industries: fermentation, cutting, glass furnace, air conditioning, waste incineration

Application field and comparison with cryogenic method

The function of oxygen blowing in open hearth furnace is combustion supporting. Its purpose is to strengthen smelting process, shorten smelting time and increase steel output of open hearth furnace. It has been proved that oxygen blowing in open hearth furnace can increase steel production by more than one time and reduce fuel consumption by 33% ~ 50%.

Oxygen used in electric furnace can accelerate the melting of furnace charge and the oxidation of impurities, which means that oxygen blowing in electric furnace can not only improve the production capacity but also improve the special quality. The oxygen consumption per ton of steel for electric furnace varies according to the different types of steel to be smelted, for example, the oxygen consumption per ton of carbon structural steel is 20-25m3, while that of high alloy steel is 25-30m3. The required oxygen concentration is 90% ~ 94%.

Blast furnace oxygen enriched blast can significantly reduce coking and increase production. According to statistics, when the oxygen concentration is increased by 1%, the iron output can be increased by 4% – 6%, and the coking can be reduced by 5% – 6%. Especially when the coal based iron making water injection rate reaches 300kg, the corresponding oxygen amount is 300m3 / iron.

When oxygen is introduced into the smelting process of non-ferrous metals, sulfur can be fully burned, smelting temperature can be maintained and smelting speed can be increased. Taking copper as an example, oxygen enriched copper smelting can save 50% energy, that is, under the same fuel consumption, the output of copper can be doubled.

|

Project category |

Cryogenic air separation oxygen plant |

VPSA PSA vacuum analytical oxygen plant |

|

Separation principle |

Liquefy the air and separate it according to different boiling points of oxygen and ammonia |

Pressure adsorption, vacuum desorption, using different adsorption capacity of oxygen and nitrogen to achieve separation |

|

Process characteristics |

The process flow is complex, requiring compression, cooling / freezing, pretreatment, expansion, liquefaction, fractionation, etc., and the operating temperature is lower than – 180 ℃ |

The process flow is simple, only high pressure / vacuum is needed; the operating temperature is normal temperature |

|

Main features of the device |

There are many moving parts, complex structure and supporting instrument and control elements; centrifugal air compressor (or oil-free air compressor), steam water separator, air purifier, heat exchanger, piston expander, filter separator |

There are few moving parts and few control elements for single supporting instrument of equipment barrel. Blower, adsorption tower, vacuum pump, oxygen storage tank |

|

Operating characteristics |

The operation is complex and can’t be opened at any time. Because it is carried out under ultra-low temperature, before the equipment is put into normal operation, there must be a process of precooling start and invalid energy consumption (low temperature liquid accumulation and heating and purging). The longer the start-up and shutdown time, the more times, the higher the unit energy consumption of the finished gas. There are many and complex operation control and monitoring points, which need to be regularly shut down for maintenance. Operators need long-term professional and technical training and rich practical operation experience. |

Easy to operate, open as you use. Operation control and monitoring are all realized by PLC, with short start-up and shutdown time less than 5 minutes. How long the well is shut down in continuous operation will not affect the working condition. There is no need to stop the machine for maintenance. The operators can operate after short-term technical training. |

|

Scope of use |

Oxygen, chlorine and hydrogen products are required; oxygen purity > 99.5% |

Extraction of single gas, purity 90-95% |

|

Maintenance features |

Due to the high precision and requirement of centrifugal air compressor, condensing steam engine and expander, the maintenance of heat exchanger in fractionation tower should be equipped with professional and experienced personnel |

The maintenance of Gufeng machine, vacuum pump and program-controlled valve are all routine maintenance, which can be completed by ordinary maintenance personnel. |

|

Civil engineering and installation features |

The unit is complex, covers a large area, needs special workshop and tower, needs anti freezing foundation, and the construction cost is high. The installation team with experience in air separation installation is required, with long installation cycle, high difficulty (fractionator) and high installation cost |

The unit has the advantages of small shape, low floor area, conventional installation, short installation cycle and low cost. |

|

Automatic program security |

There are many units, especially when using high-speed turbo expander, it is easy to affect the normal operation of the equipment due to failure. At the same time, skilled operators are required to take care of it. The operation from ultra-low temperature to high pressure has the risk of explosion and many cases. |

After the machine is started, it can be operated automatically by program control. Because it operates under normal temperature and low pressure, there are no unsafe factors. There is no danger and example of explosion. |

|

Purity adjustment |

Inconvenient purity adjustment and high oxygen production cost |

Convenient purity adjustment and low cost of oxygen production |

|

Cost of oxygen production |

Energy consumption: -1.25kwh/m³ |

Energy consumption: Less than 0.35kwh/m³ |

|

Total investment |

High investment |

Low investment |