Combustion supporting system of rock wool furnace

Energy saving mechanism of oxygen enriched combustion

Increase flame temperature

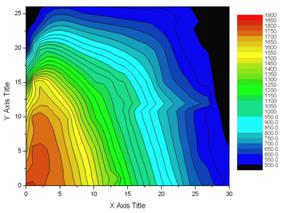

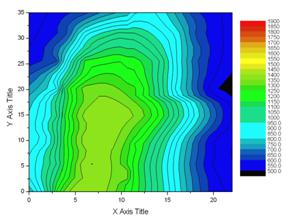

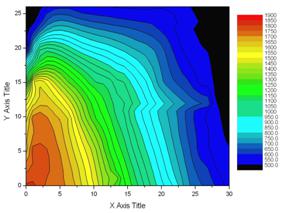

The flame temperature increases with the increase of oxygen ratio in combustion air. Generally, the concentration of 26% – 33% is the best. Because of the increase of temperature, it will be beneficial to complete combustion, shorten the flame, improve the combustion intensity and speed up the combustion.

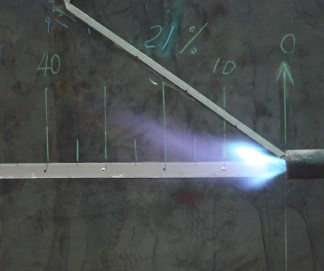

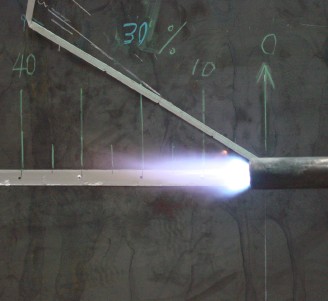

Fig. 1 flame and temperature field of gas combustion at 21% oxygen concentration

Fig. 2 flame and temperature field of gas combustion at 30% oxygen concentration

Reduce the amount of flue gas after combustion

The oxygen enriched gas which is less than 1% – 3% of the original air volume can reduce the supply air volume by 10% – 20%. Because the oxygen enriched gas can make the combustion achieve complete combustion, under high concentration, the supply air volume is reduced, the supply air reduces the amount of cold air brought in, the thermal efficiency is improved, and the general oxygen concentration can increase by 1% and the flue gas volume is decreased 2% – 2.5% of the energy of the forced draft fan is saved, while the induced air volume is correspondingly reduced, and the electric energy of the induced draft fan is saved. The exhaust heat enthalpy includes 79% of the nitrogen which does not participate in the combustion air is heated, exothermic and heat exchanged, and finally discharged to the atmosphere with the heat enthalpy of the exhaust gas temperature. This part of nitrogen does not produce heat energy, it can only take part of heat energy, and the application of oxygen enriched combustion technology reduces the amount of nitrogen gas and heat loss.

Accelerating combustion speed and promoting combustion completion

For a certain chemical reaction aA+ bB → cC + dD, the chemical reaction speed is w = kCaACbB, K is certain at a certain temperature, and the chemical reaction speed is only related to the concentration of reactants A and B. Increasing the oxygen concentration will certainly speed up the reaction. At the same time, with the increase of reaction speed, the exothermic rate of reaction will increase, and the flame temperature will also increase.

For example, the combustion rate of H2 in pure oxygen is 2-4 times of that in air, and that of natural gas is about 10.2 times. The technology of adding oxygen and supporting combustion can not only improve the combustion speed and obtain better heat conduction, but also help the combustion reaction, promote the combustion completely and eliminate the soot pollution fundamentally.

Reduce fuel ignition temperature

The ignition temperature of fuel is not constant. For example, the ignition temperature of CO in air is 609 ℃, while that in pure oxygen is only 388 ℃. Therefore, oxygen enriched combustion can increase flame strength and heat release.

Increase of heat exchange intensity

As the oxygen rich gas is arranged in the oxygen stagnation area at the back end of the flame center to participate in combustion supporting, the flame center area is expanded, and the radiation heat exchange intensity and convection heat exchange intensity are also expanded, which is equivalent to increasing the heating area and boiler output.

Radiation law

Because the oxyfuel combustion technology can reduce the burning point of the fuel, and the combustion is complete and strong, according to the Stephen Boltzmann Law: the total radiation capacity of the blackbody is proportional to the fourth power of its absolute temperature, so the radiation energy obtained is greatly improved, and the overall thermal efficiency of the kiln is improved.

Oxygen enriched combustion proces

Requirements for manufacturing oxygen device:

Oxygen is required in any combustion process. By adding oxygen or substituting oxygen for air in the combustion process, the heat transfer can be enhanced, the flame temperature can be increased and the gas consumption can be reduced, so as to improve the total combustion effect. So it can help you improve fuel efficiency and productivity. The way of oxygen production can be cryogenic production, PSA production and other ways. The oxygen plant is not included in the scope of supply.

Process piping system:

With our advanced data collection and process monitoring means, you can effectively track the operation status of oxygen delivery, including flow, purity, pressure, temperature, etc. These information will be fed back to my control system in time, PID control and data recording will be carried out in real time, so as to make product quality more stable and production cost lower. Our system can automatically generate key production and operation data reports and print them out, so that key personnel can know the deviation between current production and process set point or target value in time.

Oxygen enrichment system:

Our specially designed oxygen enrichment system replenishes oxygen for your process by means of air vent or main air duct distributor. The system is customized according to the parameters of each cupola in order to maximize the advantages of oxygen enriched combustion – saving coke, increasing production capacity, stabilizing melting rate and improving alloy recovery.

Pure oxygen combustion system:

The closed-loop distribution system of cupola pure oxygen combustion of our company can introduce additional oxygen to reduce the consumption of coke and improve the operation of cupola. Our proprietary design combines a unique pure oxygen combustion with the ability to spray oxygen and / or solids individually through the tuyeres to enhance the flexibility of the cupola. These systems can help you reduce the amount of coke used, reduce the cost of raw materials, efficiently dispose of waste materials, and improve the melting rate.

Therefore, the oxygen enriched combustion system of cupola mainly consists of the following parts:

Oxygen enriched combustion of cupola is to add oxygen to the combustion supporting air of cupola to make its oxygen content exceed the normal value of air (21%), so as to improve the productivity of molten iron and save coke. When coal is burned in oxygen enriched state, the combustion temperature is greatly increased, which can strengthen the heat transfer in cupola and improve the productivity. With the increase of oxygen content in combustion supporting air, the amount of combustion supporting air is reduced and the air is empty Compared with the traditional process without adding oxygen, the oxygen enriched combustion technology of cupola has the following advantages:

Increase the temperature and decrease the burning loss of low silicon at the same coke consumption;

Improve productivity;

At the same tapping temperature, the consumption of coke is reduced and the content of S is reduced;

When the furnace is opened, the tapping temperature increases obviously in the same time.

Technical characteristics of oxygen enriched combustion system

Specifically:

Significant energy saving effect

The application in various combustion fields can greatly improve the thermal efficiency of combustion, for example, in the glass industry, the average oil (gas) saving is 20% – 40%, in the industrial boiler, heating furnace, iron making fault and vertical kiln of cement plant, the energy saving is 20% – 50%, significantly improving the thermal energy efficiency.

Effective prolongation of furnace life

The optimization of combustion environment makes the temperature distribution in the furnace more reasonable and effectively extends the service life of the furnace and boiler.

It is conducive to improving product output and quality

In the glass industry, the improvement of the burning condition makes the melting rate increase, the heating time shorten, the output increase, the defective rate decrease and the yield increase.

Outstanding environmental protection effect

The solid unburned matters carried in the flue gas are fully burned, the blackness of the exhaust gas is reduced, the combustible and harmful gases formed by combustion decomposition are fully burned, and the generation of harmful gases is reduced. The amount of exhaust gas is obviously reduced and the thermal pollution is reduced.

Economic benefit analysis of oxygen enriched combustion

Condition assumption: for a 5t / h Cupola, the annual working time is 3600h, the initial coke ratio is 1:10, and the yield is 70%. Economic benefit calculation:

Save 15% of coke (the price of coke is 2000 yuan / T) 5 * 3600 / 70% * (1:10) * 15% * 2000 = 770000 yuan / year.

Use oxygen 160nm3 / h (oxygen price is 1.0 yuan / m3) 160 * 3600 * 1.0 = 576000 yuan / year

About 150000 yuan has been invested in the equipment, which is a one-time investment (assumed)

Capacity increased by 15%. 5 * 3600 * 15% = 2700t / year

Conclusion: the direct economic benefit is to save production cost of 60000 yuan / year and increase production capacity by 2700t / year. Super connect and indirect benefits are quite considerable!