CYD Compressed air waste heat regeneration dryer

CYD Compressed air waste heat regeneration dryer

The waste heat regeneration dryer is a new type of adsorption dryer, which is neither of the thermal regeneration type nor of the non thermal regeneration type, but of the variable temperature and pressure adsorption. It is a kind of desiccant that is directly heated by the heat of the high temperature exhaust of the air compressor, so that the adsorbent can be completely regenerated. Therefore, it can make full use of its own energy and has the effect of energy saving.

Technical Indicators

Air handling capacity: 20-500N ㎥ / min

Working pressure: 0.6-1.0mpa (1.0-3.0mpa products can be provided according to user requirements)

Air inlet temperature: ≥ 110 ℃ ~ 150 ℃

Dew point of product gas: ≤ - 40 ℃ ~ - 70 ℃ (atmospheric dew point)

Control mode: microcomputer automatic control

Working cycle: 6-8h

Regeneration gas consumption: ≤ 1-3%

Working Principles

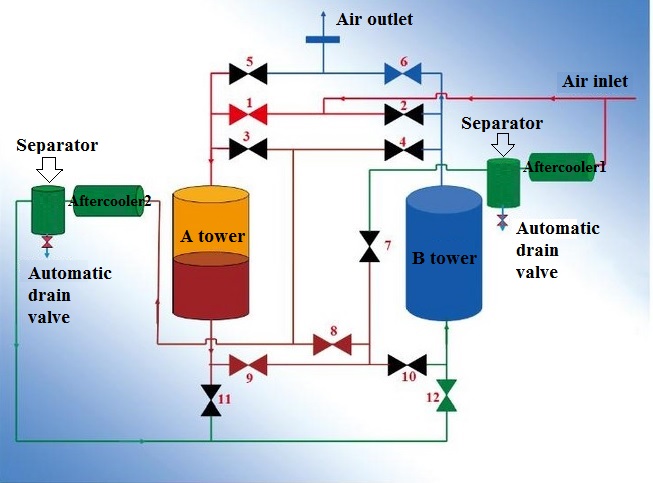

The compressed air waste heat regeneration dryer is a double tower structure, and the tower is filled with adsorbent. When one adsorption tower is in the drying process, the other adsorption tower is in the desorption process.

The compressed air residual heat regeneration dryer is mainly composed of the following equipment: two adsorption towers used alternately, one set of silencing system, one set of air cooler, one set of vapor-liquid separator, optional auxiliary electric heating system, one set of switching valve, one set of control system and air source treatment unit, etc.

Technical Features

◎Adopt the world's advanced microcomputer controller to realize communication and joint control with excellent performance.

◎High quality butterfly valve is selected for quick switching, accurate and reliable action.

◎The gas diffusion device is adopted, the air flow in the tower is evenly distributed, the unique filling mode is adopted, and the service life of the adsorbent is long

◎The waste heat of air compressor is used in the regeneration process, and the energy consumption of regeneration is low.

◎The overall layout is reasonable, the structure is compact, the installation is simple, and the use and maintenance are convenient.

Technical Parameters

|

Model |

Flow N㎥/min

|

Inlet and outlet pipe diameter DN(mm) |

Total weight Kg |

Overall dimension length width height mm |

Power supply W (auxiliary heating) |

|

CYD-40 |

40 |

100 |

2400 |

2600*1950*2750 |

220V/50HZ,100W |

|

CYD-50 |

50 |

125 |

2900 |

2600*2050*2950 |

220V/50HZ,100W |

|

CYD-60 |

60 |

125 |

3300 |

3100*2050*2950 |

220V/50HZ,100W |

|

CYD-80 |

80 |

150 |

4500 |

3300*2250*3250 |

220V/50HZ,100W |

|

CYD-100 |

100 |

150 |

6350 |

4000*2250*3250 |

220V/50HZ,150W |

|

CYD-120 |

120 |

150 |

7850 |

4000*2250*3250 |

220V/50HZ,150W |

|

CYD-150 |

150 |

200 |

9600 |

4600*2750*3450 |

220V/50HZ,150W |

|

CYD-180 |

180 |

200 |

12000 |

4900*2850*3550 |

220V/50HZ,150W |

|

CYD-200 |

200 |

200 |

13000 |

4900*2850*3850 |

220V/50HZ,200W |

|

CYD-250 |

250 |

250 |

14000 |

5400*3150*3650 |

220V/50HZ,200W |

|

CYD-300 |

300 |

250 |

16500 |

5900*3450*3950 |

220V/50HZ,200W |

|

CYD-400 |

400 |

300 |

18600 |

6300*3600*4050 |

220V/50HZ,300W |

|

CYD-500 |

500 |

350 |

19500 |

6600*3700*4150 |

220V/50HZ,300W |